Choosing the Right Butterfly Valve Type

Butterfly valves are essential in applications where tight shut-off is required. The disc opens and closes with a low-torque rotation of 90 degrees and works for any compatible application. They tend to cost less and are lighter weight, so they are preferred over other types of valves. Butterfly valves are often distinguished by the three main types: zero, double, or triple offset.

Zero Offset Butterfly Valves

These valves are designed to solve the tightening problems that can occur between the disc and seat of the butterfly valve. The stem and disc of the valve are situated in the center, and it creates a seal when the disc deforms the soft seat, causing full friction during the whole operating cycle. This valve can handle chemicals, coatings, food, some solids, and abrasive applications. One advantage is that most of the media flowing through the valve will not contact the body since the seat of the valve covers the body.

Groove Butterfly Valve

Double Offset Butterfly Valves

The double-offset structure features the stem center deviated from the center of the disc and valve. With this structure, the valve disc can leave the valve seat quickly, greatly reducing unnecessary over-compression and scraping between them. This structure also helps decrease the wearing process and prolongs the operational life of the valve. The reduction in scraping also allows the seats of these valves to be made from metal, expanding the application range of butterfly valves to high-temperature applications.

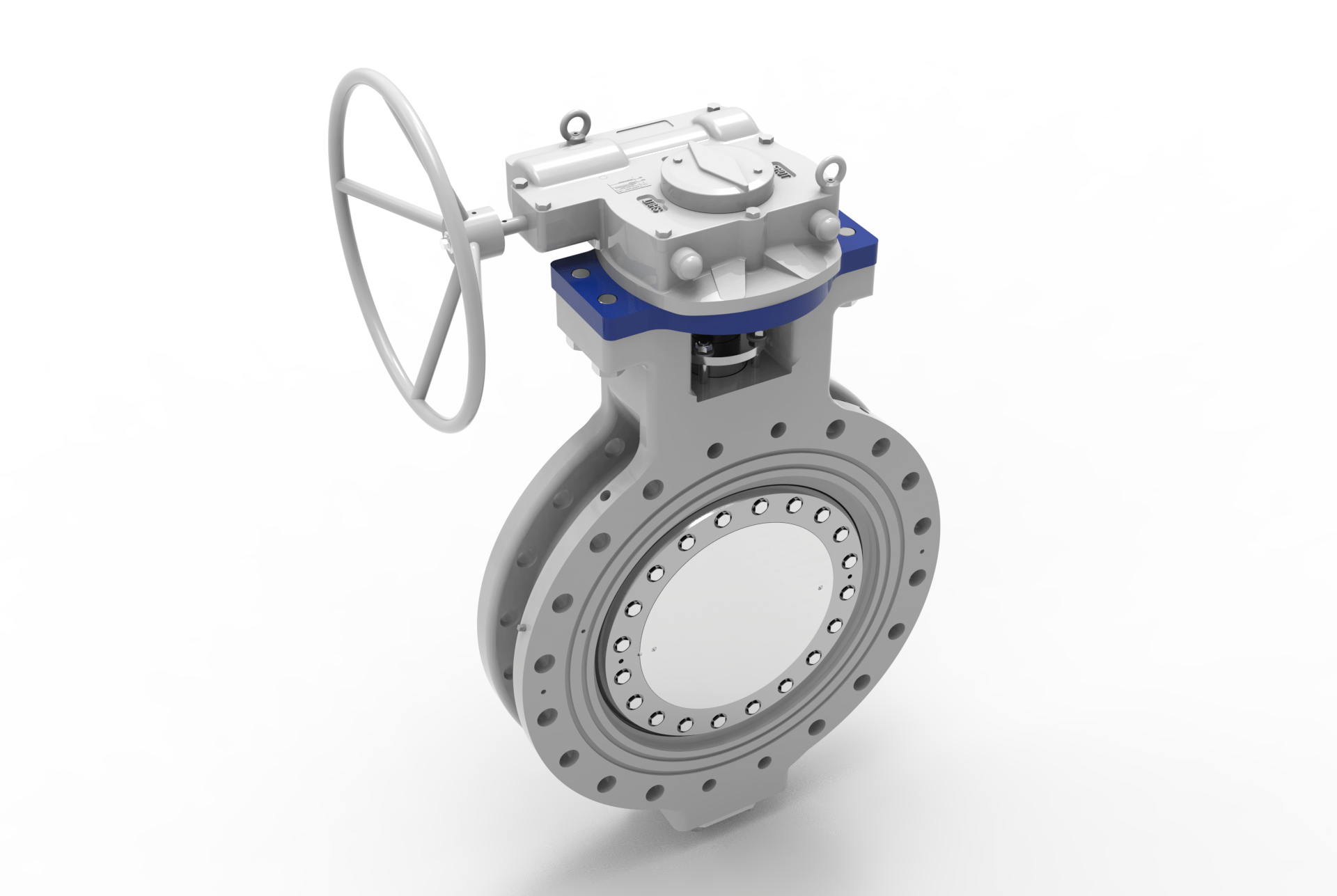

Triple offset butterfly valves

The triple offset design eliminates the rubbing between the seat and seal ring through the flow path, reducing seat and seal wear and extending cycle life. They are used in applications similar to gate valves, where a metal seat is required, and tight shutoff and/or quarter-turn actuation is desired, but triple offset butterfly valves can open and close more quickly and can be frequently operated, even if there is an emergency shutoff. This valve has low torque and is recommended for both high and low-temperature applications.

Summary

Butterfly valves come in a variety of designs and materials that are all specific to the systems involved. They are recognized in the market for excellent flow and control characteristics, tight sealing capabilities, and dependability across a wide range of applications. Choosing the right valve is essential for the success of any flow control system.