- Call Us

- +8618633052223

- njhdvlz@163.com

Jun . 21, 2024 18:10 Back to list

Supplier of 20% butterflap valve manufacturers

Understanding the 20 Way Butterfly Valve A Comprehensive Guide from Manufacturers

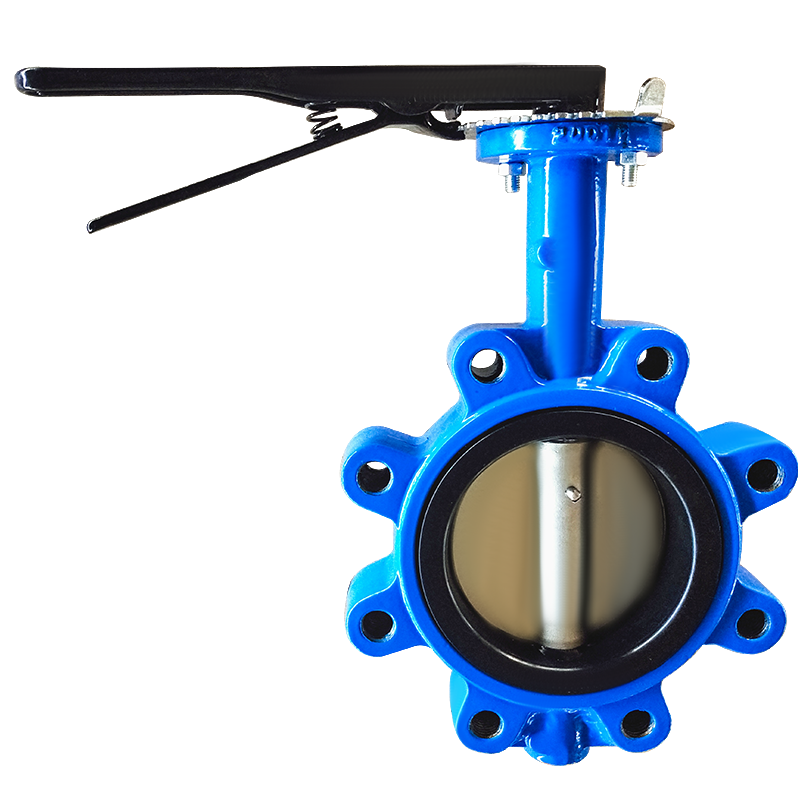

In the world of industrial piping systems, the 20 way butterfly valve stands out as a highly versatile and efficient component. This specialized valve, manufactured by industry experts, plays a pivotal role in controlling fluid flow in various applications. As a key player in the manufacturing sector, understanding the intricacies of this valve is essential for both engineers and end-users.

A 20 way butterfly valve, unlike its conventional counterparts, offers an unprecedented level of control over fluid dynamics. It is designed with multiple ports, enabling it to direct flow in 20 different directions, hence the name 20 way. This unique design makes it suitable for complex piping networks where fluid routing flexibility is paramount.

Manufacturers of these valves employ advanced materials and cutting-edge technology to ensure durability, reliability, and precision. High-grade stainless steel, carbon steel, and brass are commonly used, providing resistance against corrosion and wear, while maintaining high pressure ratings. The valve disc, or the 'butterfly,' is precisely machined to ensure smooth operation and minimal flow restriction.

The manufacturing process involves stringent quality checks at every stage, from raw material selection to final assembly. The valve's body is usually forged, ensuring strength and integrity. The butterfly disc is then attached to a stem, which can be operated manually or via an actuator for remote control The butterfly disc is then attached to a stem, which can be operated manually or via an actuator for remote control The butterfly disc is then attached to a stem, which can be operated manually or via an actuator for remote control The butterfly disc is then attached to a stem, which can be operated manually or via an actuator for remote control

The butterfly disc is then attached to a stem, which can be operated manually or via an actuator for remote control The butterfly disc is then attached to a stem, which can be operated manually or via an actuator for remote control 2 way butterfly valve manufacturer. The sealing mechanism, whether a soft seat or metal-to-metal, is carefully designed to provide leak-tight closure even under extreme conditions.

One of the key advantages of 20 way butterfly valves is their compact design, which saves space and installation costs. They are also lightweight, making them easier to handle and maintain compared to larger valve types. The quick opening and closing action reduces downtime and enhances process efficiency.

Manufacturers often customize these valves to meet specific application requirements. Be it in oil and gas, chemical processing, water treatment, or power plants, the 20 way butterfly valve can be tailored to suit the unique demands of each industry.

In conclusion, the 20 way butterfly valve, as crafted by skilled manufacturers, is a testament to engineering innovation and practicality. Its multifaceted functionality and adaptability make it a go-to solution for many complex piping systems. As the industry continues to evolve, manufacturers remain committed to refining this valve's design and performance, ensuring it remains a trusted tool in the hands of engineers worldwide.

2 way butterfly valve manufacturer. The sealing mechanism, whether a soft seat or metal-to-metal, is carefully designed to provide leak-tight closure even under extreme conditions.

One of the key advantages of 20 way butterfly valves is their compact design, which saves space and installation costs. They are also lightweight, making them easier to handle and maintain compared to larger valve types. The quick opening and closing action reduces downtime and enhances process efficiency.

Manufacturers often customize these valves to meet specific application requirements. Be it in oil and gas, chemical processing, water treatment, or power plants, the 20 way butterfly valve can be tailored to suit the unique demands of each industry.

In conclusion, the 20 way butterfly valve, as crafted by skilled manufacturers, is a testament to engineering innovation and practicality. Its multifaceted functionality and adaptability make it a go-to solution for many complex piping systems. As the industry continues to evolve, manufacturers remain committed to refining this valve's design and performance, ensuring it remains a trusted tool in the hands of engineers worldwide.

The butterfly disc is then attached to a stem, which can be operated manually or via an actuator for remote control The butterfly disc is then attached to a stem, which can be operated manually or via an actuator for remote control

The butterfly disc is then attached to a stem, which can be operated manually or via an actuator for remote control The butterfly disc is then attached to a stem, which can be operated manually or via an actuator for remote control 2 way butterfly valve manufacturer. The sealing mechanism, whether a soft seat or metal-to-metal, is carefully designed to provide leak-tight closure even under extreme conditions.

One of the key advantages of 20 way butterfly valves is their compact design, which saves space and installation costs. They are also lightweight, making them easier to handle and maintain compared to larger valve types. The quick opening and closing action reduces downtime and enhances process efficiency.

Manufacturers often customize these valves to meet specific application requirements. Be it in oil and gas, chemical processing, water treatment, or power plants, the 20 way butterfly valve can be tailored to suit the unique demands of each industry.

In conclusion, the 20 way butterfly valve, as crafted by skilled manufacturers, is a testament to engineering innovation and practicality. Its multifaceted functionality and adaptability make it a go-to solution for many complex piping systems. As the industry continues to evolve, manufacturers remain committed to refining this valve's design and performance, ensuring it remains a trusted tool in the hands of engineers worldwide.

2 way butterfly valve manufacturer. The sealing mechanism, whether a soft seat or metal-to-metal, is carefully designed to provide leak-tight closure even under extreme conditions.

One of the key advantages of 20 way butterfly valves is their compact design, which saves space and installation costs. They are also lightweight, making them easier to handle and maintain compared to larger valve types. The quick opening and closing action reduces downtime and enhances process efficiency.

Manufacturers often customize these valves to meet specific application requirements. Be it in oil and gas, chemical processing, water treatment, or power plants, the 20 way butterfly valve can be tailored to suit the unique demands of each industry.

In conclusion, the 20 way butterfly valve, as crafted by skilled manufacturers, is a testament to engineering innovation and practicality. Its multifaceted functionality and adaptability make it a go-to solution for many complex piping systems. As the industry continues to evolve, manufacturers remain committed to refining this valve's design and performance, ensuring it remains a trusted tool in the hands of engineers worldwide. Latest news

-

Premium 2.5 Inch Butterfly Valve with GPT-4 Turbo

NewsAug.04,2025

-

Compact Double Flanged Short Pattern Butterfly Valve | High Efficiency

NewsAug.03,2025

-

Stainless Steel Sanitary Butterfly Valve | Hygienic & Durable

NewsAug.02,2025

-

Double Flanged Short Pattern Butterfly Valve | Compact, Efficient Flow

NewsAug.01,2025

-

Precise 3-Inch Butterfly Valve Dimensions | Durable Flow

NewsJul.31,2025

-

3 Butterfly Valve Dimensions | GPT-4 Turbo Precision Specs

NewsJul.31,2025