- Call Us

- +8618633052223

- njhdvlz@163.com

Jun . 28, 2024 15:20 Back to list

High-Quality Rubber Butterfly Valve Manufacturer - Durable & Reliable

The Pivotal Role of Butterfly Valve Rubber Factories in Modern Industry

In the realm of industrial engineering and fluid control systems, the butterfly valve rubber factory holds a significant position. These specialized facilities are the backbone of manufacturing high-quality butterfly valves, an essential component in various industries including water treatment, chemical processing, oil and gas, and power generation.

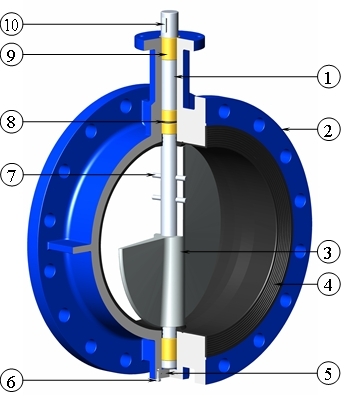

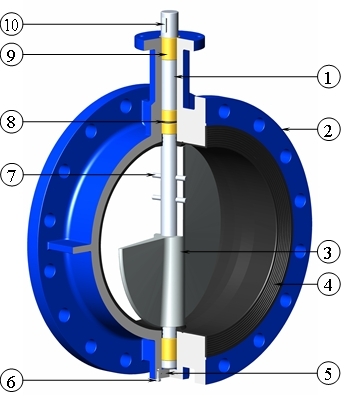

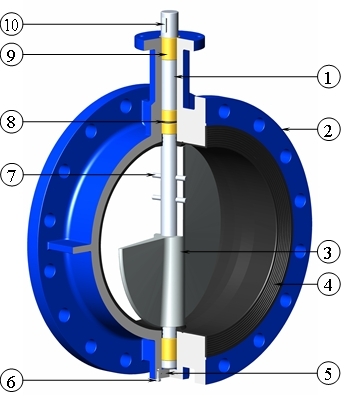

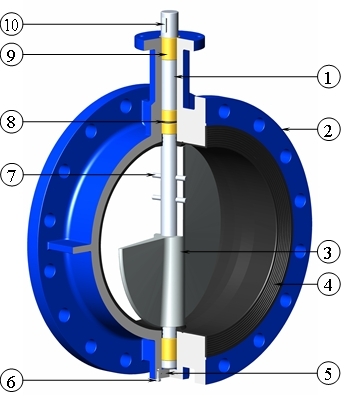

A butterfly valve, named for its resemblance to a butterfly's wings when open, is a type of valve that uses a disc to regulate flow. The rubber component in these valves serves as the sealing element, ensuring a tight shut-off and preventing leaks. The rubber material, usually made from elastomers like EPDM, NBR, or Viton, provides flexibility, durability, and resistance to harsh chemicals, making it ideal for different operating conditions.

The manufacturing process in a butterfly valve rubber factory is a meticulous blend of technology and craftsmanship. It starts with the selection of premium raw materials, followed by precision molding to shape the rubber components. The rubber is then cured, a process that involves heating to activate the curing agents and create a strong, resilient final product. Quality control is paramount, with each valve undergoing rigorous testing to ensure optimal performance and longevity.

These factories also focus on customization, catering to specific client needs. They can tailor the rubber compound to withstand extreme temperatures, resist particular chemicals, or meet stringent industry standards like API, ANSI, or DIN They can tailor the rubber compound to withstand extreme temperatures, resist particular chemicals, or meet stringent industry standards like API, ANSI, or DIN They can tailor the rubber compound to withstand extreme temperatures, resist particular chemicals, or meet stringent industry standards like API, ANSI, or DIN They can tailor the rubber compound to withstand extreme temperatures, resist particular chemicals, or meet stringent industry standards like API, ANSI, or DIN

They can tailor the rubber compound to withstand extreme temperatures, resist particular chemicals, or meet stringent industry standards like API, ANSI, or DIN They can tailor the rubber compound to withstand extreme temperatures, resist particular chemicals, or meet stringent industry standards like API, ANSI, or DIN butterfly valve rubber factory. Moreover, they often integrate advanced technologies like 3D printing and automation to enhance efficiency and precision in production.

Beyond the technical aspects, butterfly valve rubber factories contribute significantly to sustainable development. Their products play a crucial role in efficient fluid management, reducing energy consumption and waste. They also invest in eco-friendly manufacturing practices, recycling waste materials, and minimizing environmental impact.

Furthermore, these factories are not just centers of production; they are hubs of innovation. Continuous research and development drive advancements in valve design, material science, and production techniques, leading to more efficient, durable, and sustainable butterfly valves.

In conclusion, butterfly valve rubber factories are more than mere manufacturing units; they are integral to the global infrastructure. Their commitment to quality, customization, sustainability, and innovation ensures that they remain at the forefront of fluid control solutions. As industries continue to evolve, these factories will continue to shape the future of valve technology, supporting progress while safeguarding the environment.

butterfly valve rubber factory. Moreover, they often integrate advanced technologies like 3D printing and automation to enhance efficiency and precision in production.

Beyond the technical aspects, butterfly valve rubber factories contribute significantly to sustainable development. Their products play a crucial role in efficient fluid management, reducing energy consumption and waste. They also invest in eco-friendly manufacturing practices, recycling waste materials, and minimizing environmental impact.

Furthermore, these factories are not just centers of production; they are hubs of innovation. Continuous research and development drive advancements in valve design, material science, and production techniques, leading to more efficient, durable, and sustainable butterfly valves.

In conclusion, butterfly valve rubber factories are more than mere manufacturing units; they are integral to the global infrastructure. Their commitment to quality, customization, sustainability, and innovation ensures that they remain at the forefront of fluid control solutions. As industries continue to evolve, these factories will continue to shape the future of valve technology, supporting progress while safeguarding the environment.

They can tailor the rubber compound to withstand extreme temperatures, resist particular chemicals, or meet stringent industry standards like API, ANSI, or DIN They can tailor the rubber compound to withstand extreme temperatures, resist particular chemicals, or meet stringent industry standards like API, ANSI, or DIN

They can tailor the rubber compound to withstand extreme temperatures, resist particular chemicals, or meet stringent industry standards like API, ANSI, or DIN They can tailor the rubber compound to withstand extreme temperatures, resist particular chemicals, or meet stringent industry standards like API, ANSI, or DIN butterfly valve rubber factory. Moreover, they often integrate advanced technologies like 3D printing and automation to enhance efficiency and precision in production.

Beyond the technical aspects, butterfly valve rubber factories contribute significantly to sustainable development. Their products play a crucial role in efficient fluid management, reducing energy consumption and waste. They also invest in eco-friendly manufacturing practices, recycling waste materials, and minimizing environmental impact.

Furthermore, these factories are not just centers of production; they are hubs of innovation. Continuous research and development drive advancements in valve design, material science, and production techniques, leading to more efficient, durable, and sustainable butterfly valves.

In conclusion, butterfly valve rubber factories are more than mere manufacturing units; they are integral to the global infrastructure. Their commitment to quality, customization, sustainability, and innovation ensures that they remain at the forefront of fluid control solutions. As industries continue to evolve, these factories will continue to shape the future of valve technology, supporting progress while safeguarding the environment.

butterfly valve rubber factory. Moreover, they often integrate advanced technologies like 3D printing and automation to enhance efficiency and precision in production.

Beyond the technical aspects, butterfly valve rubber factories contribute significantly to sustainable development. Their products play a crucial role in efficient fluid management, reducing energy consumption and waste. They also invest in eco-friendly manufacturing practices, recycling waste materials, and minimizing environmental impact.

Furthermore, these factories are not just centers of production; they are hubs of innovation. Continuous research and development drive advancements in valve design, material science, and production techniques, leading to more efficient, durable, and sustainable butterfly valves.

In conclusion, butterfly valve rubber factories are more than mere manufacturing units; they are integral to the global infrastructure. Their commitment to quality, customization, sustainability, and innovation ensures that they remain at the forefront of fluid control solutions. As industries continue to evolve, these factories will continue to shape the future of valve technology, supporting progress while safeguarding the environment. Latest news

-

Double Flanged Short Pattern Butterfly Valve | Compact, Efficient Flow

NewsAug.01,2025

-

Precise 3-Inch Butterfly Valve Dimensions | Durable Flow

NewsJul.31,2025

-

3 Butterfly Valve Dimensions | GPT-4 Turbo Precision Specs

NewsJul.31,2025

-

Stainless Steel Sanitary Butterfly Valve for Hygienic Flow Control

NewsJul.30,2025

-

High-Performance Groove Butterfly Valve for Easy Installation

NewsJul.30,2025

-

High-Quality 2 Inch Butterfly Valve for Precise Flow Control

NewsJul.29,2025