- Call Us

- +8618633052223

- njhdvlz@163.com

Jun . 21, 2024 18:11 Back to list

Titan Wafer Check Valve providers

Understanding Titan Wafer Check Valve Suppliers and Their Importance

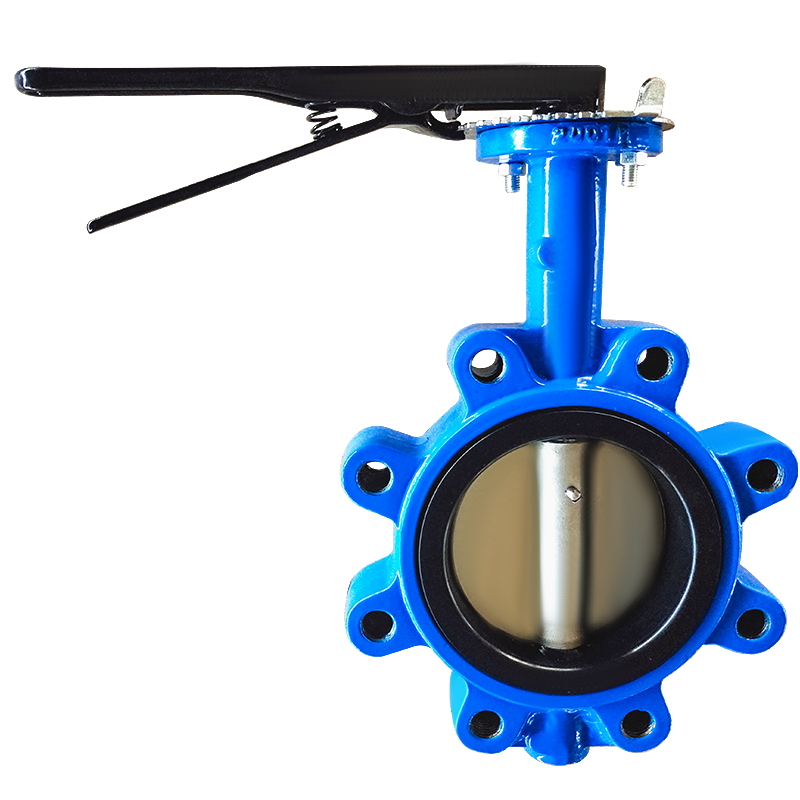

In the world of industrial fluid control systems, the Titan Wafer Check Valve stands as a critical component, ensuring the unidirectional flow of fluids and preventing backflow. These valves, made primarily from titanium, offer exceptional durability, corrosion resistance, and lightweight properties, making them ideal for high-pressure and corrosive environments. This article delves into the significance of Titan Wafer Check Valves and the suppliers who cater to this specialized market.

Titan Wafer Check Valves are designed with a wafer-style configuration, allowing for compact installation between pipeline flanges. The valve's slim profile reduces system weight and space requirements while maintaining robust performance. The use of titanium as the primary material enhances its resistance to harsh chemicals, seawater, and high-temperature applications, making it a popular choice in industries such as petrochemicals, power generation, and aerospace.

The role of suppliers in the Titan Wafer Check Valve market is pivotal. They not only source and provide these specialized valves but also offer technical expertise, customization options, and after-sales support. Suppliers collaborate with manufacturers to ensure that each valve meets stringent industry standards, such as API, ASME, and ISO, ensuring safety and reliability.

One of the key attributes of a reliable supplier is their ability to provide tailored solutions. This could involve customizing valve sizes, pressure ratings, or material coatings to meet specific application requirements. Additionally, they often stock a wide range of valve types, including swing check, lift check, and spring-loaded check valves, catering to diverse industry needs Additionally, they often stock a wide range of valve types, including swing check, lift check, and spring-loaded check valves, catering to diverse industry needs Additionally, they often stock a wide range of valve types, including swing check, lift check, and spring-loaded check valves, catering to diverse industry needs Additionally, they often stock a wide range of valve types, including swing check, lift check, and spring-loaded check valves, catering to diverse industry needs

Additionally, they often stock a wide range of valve types, including swing check, lift check, and spring-loaded check valves, catering to diverse industry needs Additionally, they often stock a wide range of valve types, including swing check, lift check, and spring-loaded check valves, catering to diverse industry needs titan wafer check valve suppliers.

Another crucial aspect is the supplier's commitment to quality assurance. They conduct rigorous testing on the valves, including pressure tests, material analysis, and functionality checks, to guarantee optimal performance. Moreover, a good supplier should have a well-established supply chain, ensuring timely deliveries and minimizing downtime for clients.

Suppliers also play an educational role, assisting customers in selecting the right valve for their application by considering factors like fluid properties, system pressure, and temperature. Their in-depth knowledge of the product and its applications can help prevent potential issues and optimize system efficiency.

In conclusion, Titan Wafer Check Valve suppliers are vital partners in the fluid control industry. They bridge the gap between innovative valve technology and end-users, providing tailored solutions, quality products, and expert advice. As the demand for high-performance, corrosion-resistant valves continues to grow, the importance of reliable suppliers in the Titan Wafer Check Valve sector becomes increasingly evident. Whether it's petrochemical plants, power stations, or marine engineering, these suppliers ensure the seamless operation of critical infrastructure through their commitment to quality and customer satisfaction.

titan wafer check valve suppliers.

Another crucial aspect is the supplier's commitment to quality assurance. They conduct rigorous testing on the valves, including pressure tests, material analysis, and functionality checks, to guarantee optimal performance. Moreover, a good supplier should have a well-established supply chain, ensuring timely deliveries and minimizing downtime for clients.

Suppliers also play an educational role, assisting customers in selecting the right valve for their application by considering factors like fluid properties, system pressure, and temperature. Their in-depth knowledge of the product and its applications can help prevent potential issues and optimize system efficiency.

In conclusion, Titan Wafer Check Valve suppliers are vital partners in the fluid control industry. They bridge the gap between innovative valve technology and end-users, providing tailored solutions, quality products, and expert advice. As the demand for high-performance, corrosion-resistant valves continues to grow, the importance of reliable suppliers in the Titan Wafer Check Valve sector becomes increasingly evident. Whether it's petrochemical plants, power stations, or marine engineering, these suppliers ensure the seamless operation of critical infrastructure through their commitment to quality and customer satisfaction.

Additionally, they often stock a wide range of valve types, including swing check, lift check, and spring-loaded check valves, catering to diverse industry needs Additionally, they often stock a wide range of valve types, including swing check, lift check, and spring-loaded check valves, catering to diverse industry needs

Additionally, they often stock a wide range of valve types, including swing check, lift check, and spring-loaded check valves, catering to diverse industry needs Additionally, they often stock a wide range of valve types, including swing check, lift check, and spring-loaded check valves, catering to diverse industry needs titan wafer check valve suppliers.

Another crucial aspect is the supplier's commitment to quality assurance. They conduct rigorous testing on the valves, including pressure tests, material analysis, and functionality checks, to guarantee optimal performance. Moreover, a good supplier should have a well-established supply chain, ensuring timely deliveries and minimizing downtime for clients.

Suppliers also play an educational role, assisting customers in selecting the right valve for their application by considering factors like fluid properties, system pressure, and temperature. Their in-depth knowledge of the product and its applications can help prevent potential issues and optimize system efficiency.

In conclusion, Titan Wafer Check Valve suppliers are vital partners in the fluid control industry. They bridge the gap between innovative valve technology and end-users, providing tailored solutions, quality products, and expert advice. As the demand for high-performance, corrosion-resistant valves continues to grow, the importance of reliable suppliers in the Titan Wafer Check Valve sector becomes increasingly evident. Whether it's petrochemical plants, power stations, or marine engineering, these suppliers ensure the seamless operation of critical infrastructure through their commitment to quality and customer satisfaction.

titan wafer check valve suppliers.

Another crucial aspect is the supplier's commitment to quality assurance. They conduct rigorous testing on the valves, including pressure tests, material analysis, and functionality checks, to guarantee optimal performance. Moreover, a good supplier should have a well-established supply chain, ensuring timely deliveries and minimizing downtime for clients.

Suppliers also play an educational role, assisting customers in selecting the right valve for their application by considering factors like fluid properties, system pressure, and temperature. Their in-depth knowledge of the product and its applications can help prevent potential issues and optimize system efficiency.

In conclusion, Titan Wafer Check Valve suppliers are vital partners in the fluid control industry. They bridge the gap between innovative valve technology and end-users, providing tailored solutions, quality products, and expert advice. As the demand for high-performance, corrosion-resistant valves continues to grow, the importance of reliable suppliers in the Titan Wafer Check Valve sector becomes increasingly evident. Whether it's petrochemical plants, power stations, or marine engineering, these suppliers ensure the seamless operation of critical infrastructure through their commitment to quality and customer satisfaction. Latest news

-

Double Flanged Short Pattern Butterfly Valve | Compact, Efficient Flow

NewsAug.01,2025

-

Precise 3-Inch Butterfly Valve Dimensions | Durable Flow

NewsJul.31,2025

-

3 Butterfly Valve Dimensions | GPT-4 Turbo Precision Specs

NewsJul.31,2025

-

Stainless Steel Sanitary Butterfly Valve for Hygienic Flow Control

NewsJul.30,2025

-

High-Performance Groove Butterfly Valve for Easy Installation

NewsJul.30,2025

-

High-Quality 2 Inch Butterfly Valve for Precise Flow Control

NewsJul.29,2025